Mechanical engineering is a dynamic and challenging field that combines principles from physics, mathematics, and material science to design, analyze, and manufacture mechanical systems. For sophomore students embarking on their mechanical engineering journey, hands-on DIY projects can be a fun, practical, and educational way to reinforce the concepts learned in class. These projects not only develop technical skills but also foster creativity, problem-solving abilities, and teamwork. Here are several simple DIY projects ideal for sophomore mechanical engineers in the USA, offering opportunities to practice core engineering concepts.

1. DIY Mechanical Arm (Robotic Arm)

A mechanical arm is one of the most fundamental engineering projects for a sophomore student. This project provides a great introduction to robotics, control systems, and mechanical design. It also gives students an opportunity to work with motors, servos, and sensors, making it a valuable hands-on project.

Components:

- Servo motors (for movement)

- Plastic or wooden materials (for arm structure)

- Wires and jumper cables

- Arduino board (for control)

- Microcontroller (like Arduino)

- Sensors (optional, for feedback)

- Screws, nuts, and bolts

Process:

- Design the mechanical arm with specific degrees of freedom (DOF) for each joint, such as the shoulder, elbow, and wrist.

- Use servo motors to control each of the joints. An Arduino board will act as the control system.

- Write a program for the Arduino to control the movement of the arm based on input commands.

- Assemble the arm using the selected materials (wood, plastic, or even 3D printed parts).

- Test and calibrate the arm’s movements.

By building this project, sophomore students will learn about kinematics, actuation systems, and basic programming, along with mechanical assembly and testing.

2. Homemade Wind Turbine

Creating a simple wind turbine is an excellent way for mechanical engineering students to learn about renewable energy systems, fluid mechanics, and energy conversion. This project allows students to explore the principles of aerodynamics and mechanical design, as well as the integration of electrical components for generating power.

Components:

- DC motor (for generating electricity)

- PVC pipes (for the frame)

- Wooden or plastic blades (for the turbine)

- Wires and a multimeter (to measure the output)

- Diode (to prevent backflow of current)

- Small battery (for storage)

- Drill and screws for assembly

Process:

- Begin by designing the turbine blades. For efficiency, they should be angled to catch the wind and rotate the motor.

- Build the frame of the turbine using PVC pipes or lightweight materials.

- Attach the DC motor to the frame and connect the blades so they can rotate the motor shaft when the wind blows.

- Wire the motor to a small battery or LED light for energy storage or visual feedback.

- Test the turbine by placing it outside in a windy area and measure the voltage output with a multimeter.

This project is a great introduction to energy systems, fluid dynamics, and mechanical efficiency. It also teaches students how to optimize designs for real-world performance.

3. Pneumatic Lifting Mechanism

Pneumatics is a key area in mechanical engineering, focusing on the use of pressurized air to generate force and motion. Building a pneumatic lifting mechanism teaches students about fluid dynamics, control systems, and actuator design.

Components:

- Pneumatic cylinders

- Air compressor or hand pump

- Tubing and fittings

- Pressure regulator

- Control valves

- Frame (can be made from metal or wood)

- Sensors (optional)

Process:

- Design a lifting system where a pneumatic cylinder is used to lift an object. The cylinder’s piston will move as pressurized air is applied.

- Create a frame for the system, making sure it is stable and able to support the load.

- Connect the pneumatic cylinder to the air compressor or hand pump using tubing and fittings.

- Use control valves to regulate the flow of air and control the lifting and lowering of the object.

- Test the system, adjusting the pressure regulator to achieve the desired lift.

Students will gain practical experience in pneumatics, control systems, and mechanical design. Additionally, they will learn the importance of pressure and flow in creating efficient systems.

4. Mechanical Clocks

Building a mechanical clock is an engaging way to explore gear mechanisms, rotational motion, and timekeeping systems. This project gives students an understanding of mechanical linkages and gear ratios.

Components:

- Gears (brass or plastic)

- Springs

- Clock hands

- Frame (wood or metal)

- Axles and bushings

- Glue, screws, and other assembly tools

Process:

- Design the clock mechanism, including the arrangement of gears that control the movement of the clock hands.

- Build the frame to house the gears and other components.

- Assemble the gears, ensuring that they are meshed correctly for proper motion.

- Install the clock hands and test the system to ensure the clock works correctly.

- Add a spring or weight-driven mechanism to keep the clock running.

This project allows students to delve into gear design, mechanical power transmission, and motion control. They also gain experience in understanding mechanical time-keeping systems.

5. Ball-and-Socket Joint

The ball-and-socket joint is a basic yet profound mechanical design that mimics human joints, such as the shoulder or hip. This project helps students understand forces, torques, and mechanical linkages, making it an excellent learning tool.

Components:

- Ball (plastic or metal)

- Socket (3D printed or cast metal)

- Bearings (optional, for smoother movement)

- Springs (for locking mechanisms)

- Fasteners

Process:

- Design the ball-and-socket joint, ensuring the ball can move freely within the socket while maintaining a secure fit.

- Choose materials that are durable and allow for smooth rotation.

- Assemble the socket and ball, using bearings if desired for added stability.

- Test the joint by applying forces to see how the ball moves within the socket and how the joint reacts to different load conditions.

This project gives students a deeper understanding of joint mechanisms and is a simple yet effective way to learn about mechanical motion and force transmission.

6. Simple Hydraulic Lift

A hydraulic lift operates on the principle of fluid pressure and is a common application of fluid mechanics. Building a simple hydraulic lift teaches students about Pascal’s Law, force multiplication, and system efficiency.

Components:

- Syringes (large and small for the hydraulic system)

- Tubing

- Water or oil (as hydraulic fluid)

- Wooden or metal base for the lift

- Small objects for lifting (weights)

Process:

- Connect two syringes using tubing. The smaller syringe will act as the input, and the larger syringe will be the output, transferring the hydraulic pressure.

- Fill the syringes with water or hydraulic fluid and seal the system to avoid leakage.

- Design the base of the lift, ensuring it can support the hydraulic cylinders and the object being lifted.

- Test the lift by pushing the small syringe to see how much weight the system can lift using hydraulic pressure.

Through this project, students will learn about fluid dynamics, force transmission, and how simple hydraulic systems work in real-world applications like car lifts or construction equipment.

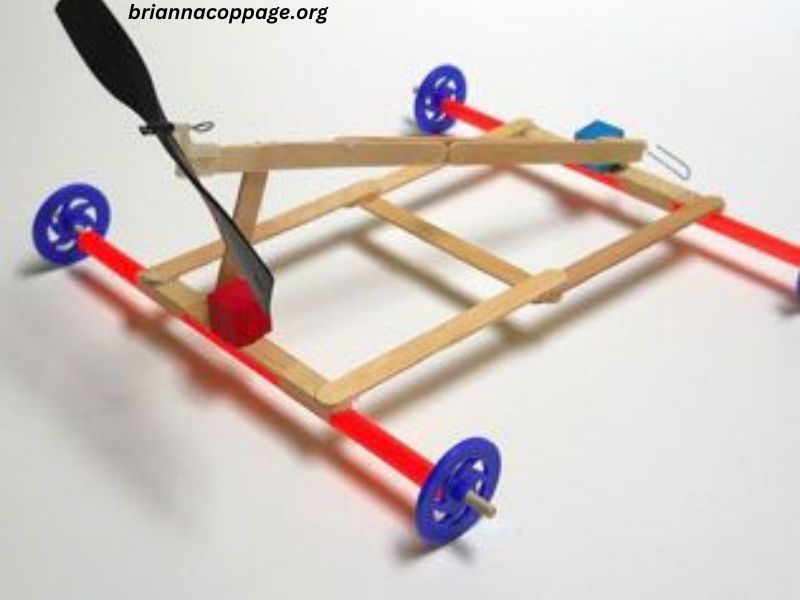

7. Miniature Go-Kart

Building a small go-kart is a thrilling yet educational project that covers a broad spectrum of mechanical engineering topics, such as vehicle dynamics, suspension systems, and power transmission. This project is perfect for students who want to dive deeper into mechanical design and testing.

Components:

- Go-kart frame (can be welded or bolted)

- Wheels and axles

- Electric or gas-powered motor

- Steering mechanism (rack and pinion or lever)

- Braking system

- Seats and safety harnesses

Process:

- Design the frame of the go-kart, ensuring it is lightweight yet strong enough to handle the stresses of driving.

- Choose an appropriate motor and design the power transmission system (chain or belt drive).

- Install the wheels, axles, and steering mechanism.

- Test the kart and make necessary adjustments to the suspension and braking system.

Building a go-kart introduces students to mechanical design, safety considerations, and automotive systems. It provides a comprehensive view of engineering design, from conceptualization to testing.

Conclusion

DIY projects are a great way for sophomore mechanical engineering students to develop their skills and knowledge while working on tangible, hands-on creations. By tackling projects such as a mechanical arm, wind turbine, pneumatic lift, or even a miniature go-kart, students not only gain practical experience but also reinforce their understanding of core mechanical engineering principles. These projects foster creativity, teamwork, and problem-solving, all of which are essential for a successful career in mechanical .